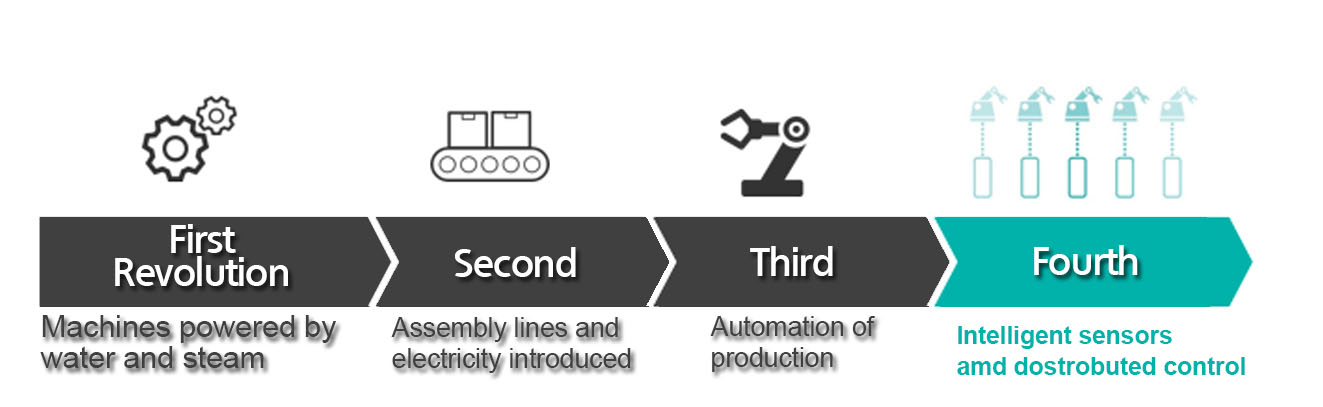

There’s a huge wave coming (that has already arrived in fact at several companies), known as Industry 4.0.

Industry 4.0 generally refers to implementation of Artificial Intelligence, Big Data, Augemented Reality, and the Industrial Internet of Things (IIoT) in factories. Although there is no formal, official definition, many consider the predecessors of Industry 4.0 to be industrial revolution using water and steam power (1.0); the use of electric power, motors, and basic closed-loop control in industry (2.0); and the addition of computing power to industrial processes and control (3.0).

We are already working with companies like Fiat Chrysler Automobile, Toyota and Claas, providing support and solutions under the Industry 4.0 umbrella, focused in Augmented and Virtual Reality and Computer Vision.

While much of the IoT, Augmented Reality and Big Data attention (and hype) has been focused on mass-market applications, the reality is that Industry 4.0-related opportunity is at least equal, and likely higher, in industrial situations.

We design and deploy Industry 4.0 solutions, integrating our extended expertise in AR/Wearables, along with IoT, BPM (Business Process Management), Big Data and System Integrations.

Here are some use cases for AR that we are deploying:

- Remote Support using Google Glasses or Realwear

According to the facilities requirements, weather, indoor/outdoor and other conditions, we provide the best glasses for each case, selecting from the current available glasses like Google Glass, Realwear and Moverio, to the more immersive AR Glasses like Microsoft Hololens or Magic Leap.

Remote support solutions drastically reduce the off-line times of machinery and costs of sending high skilled technicians to different areas in the facilities or away from them. We have deployed these solutions for Maintenance of Equipments, Traffic Lights Maintenance, and other use cases.

VR Trainers save time and resources because it is proven by several studies that the users learn better and faster. We have deployed VR trainers with 360 videos or VR scenarios, to train in safety, welding, manufacturing and other processes. Here we can see a part of the FCA – Fiat Chrysler Automobile VR Trainer that we created.